Otta slate is taken out of our range

We have taken Otta slate out of the range, as this type of slate is no longer produced by us.

Our two slate types from Oppdal and Offerdal have a timeless appearance and come in different surfaces, giving you a variety of colours, tones and shades to choose from:

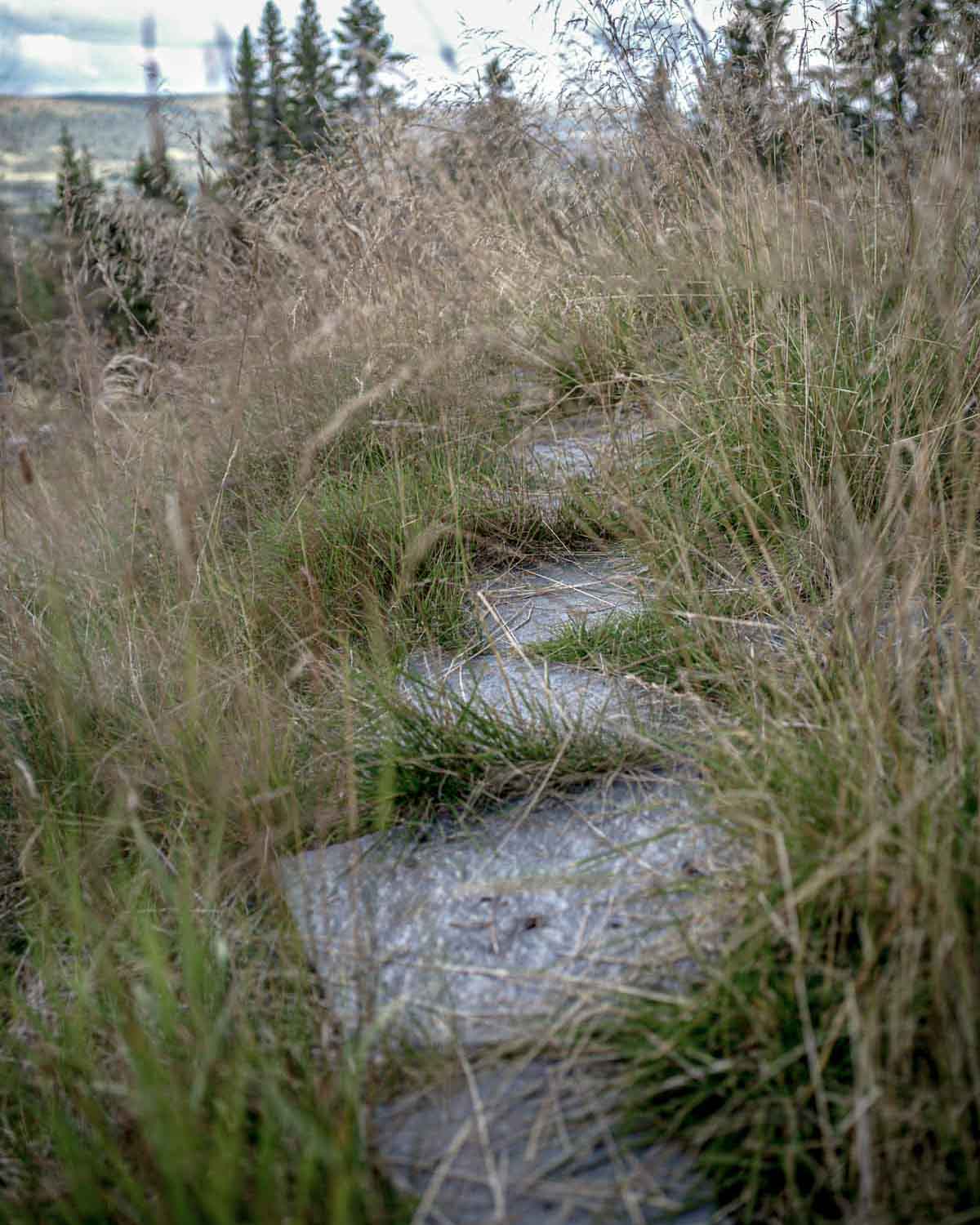

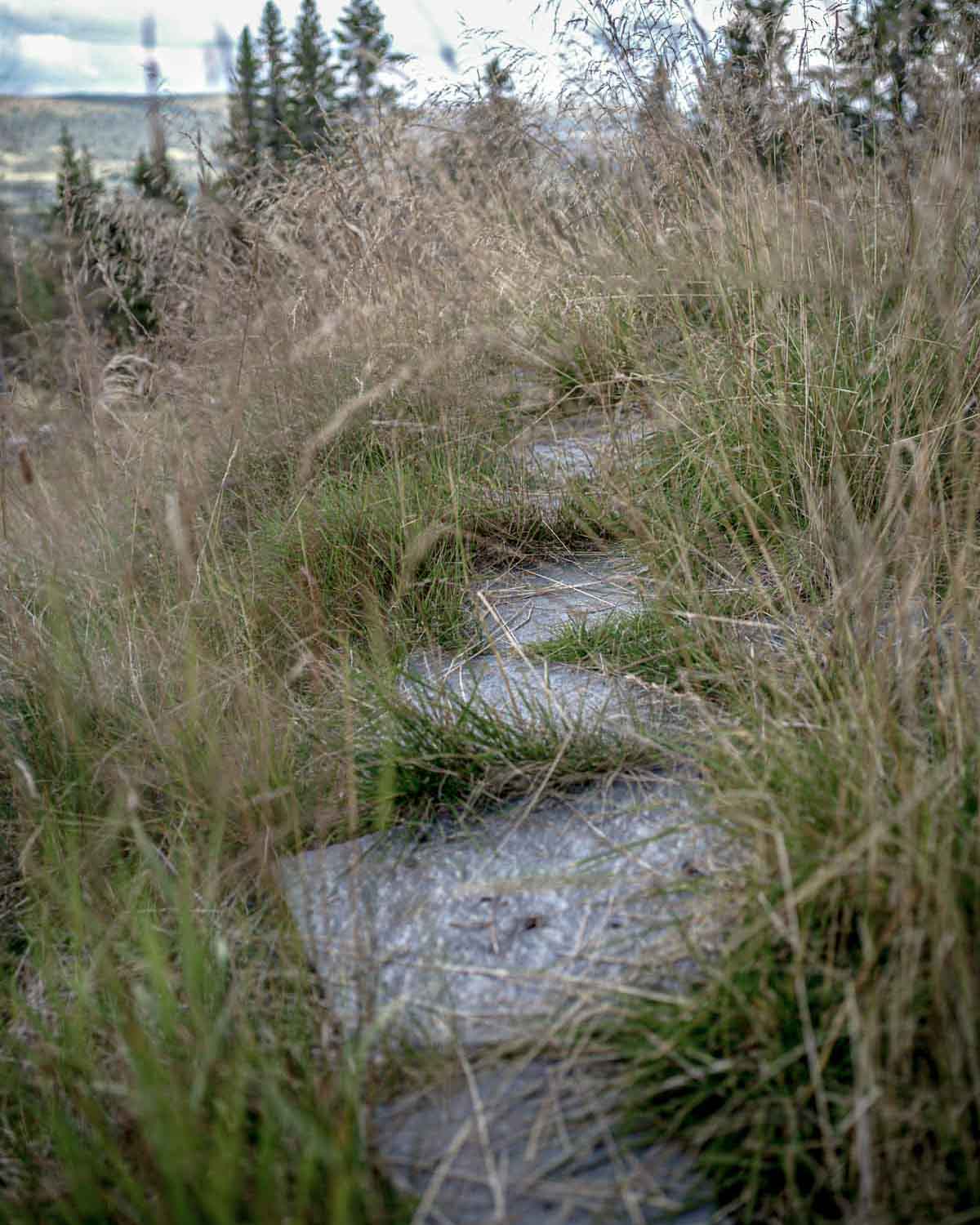

Many are surprised by the bright, warm hues of Lys Oppdal slate and how it blends so elegantly into a modern Scandinavian interior. Outside, it’s a much-loved classic, not only for its beautiful surface, but also for its edges.

The elegant darker grey, slightly wavy surface of Offerdal slate is equally suitable for interiors and exteriors. Want to create a little extra magic? You’ll love the slate’s ability to reflect colours and light at different times of the day and in different seasons.