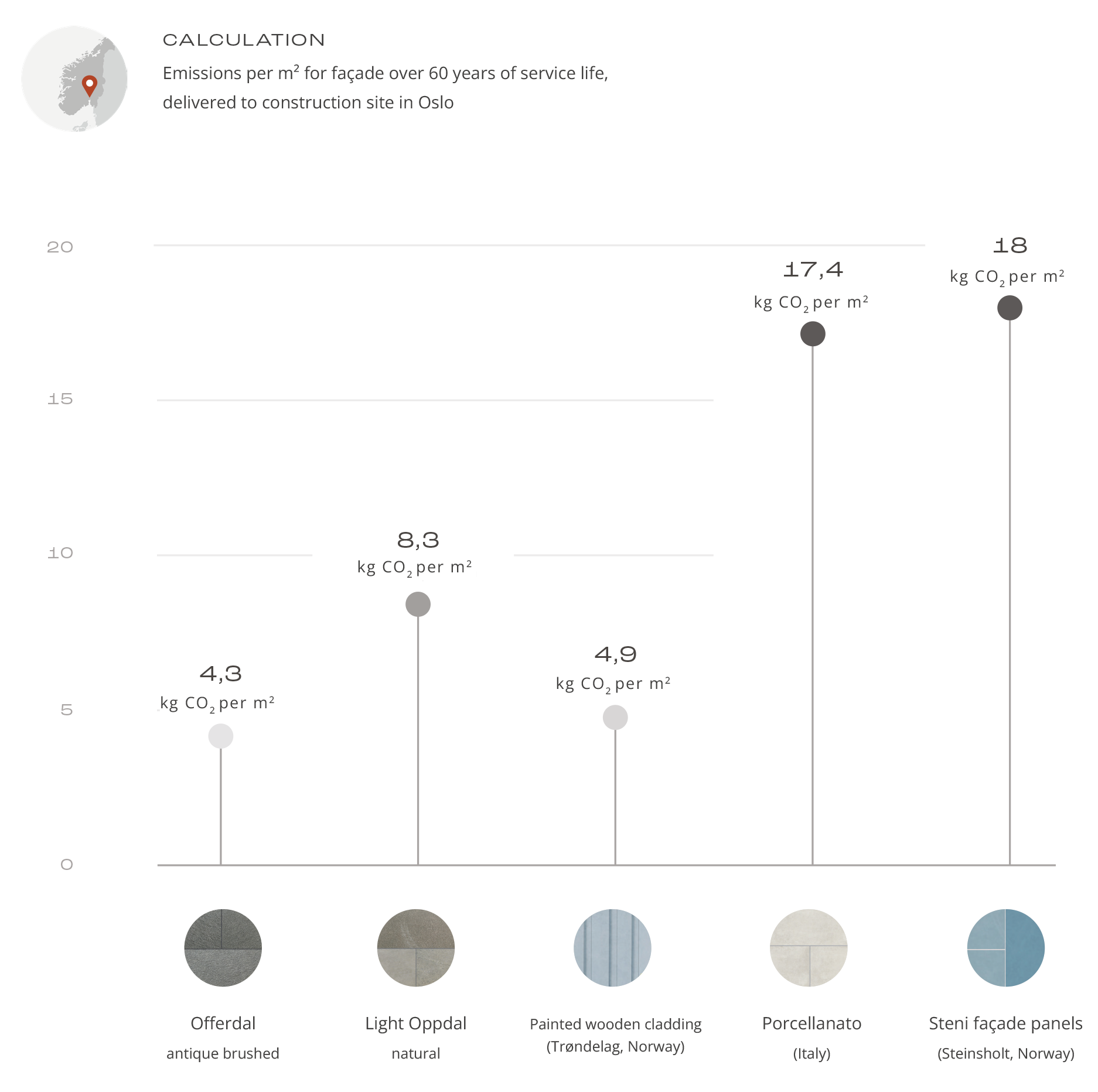

Environmental comparison: slate versus alternative materials

Slate cladding installed with hook systems is compared to painted wooden cladding (Norway), Porcellanato (Italy), and composite panels (Norway).

Result:

Light Oppdal natural slate has significantly lower greenhouse gas emissions than Porcellanato, with a reduction of approx. 9,000 kg CO₂-eq for a 200 m² façade. Offerdal slate also has lower emissions than Steni.

Specifying Light Oppdal Natural slate instead of Porcellanato from Italy for a 200 m² façade reduces emissions equivalent to the electricity consumption for heating a typical Norwegian detached house (150 m²) for nearly four years.

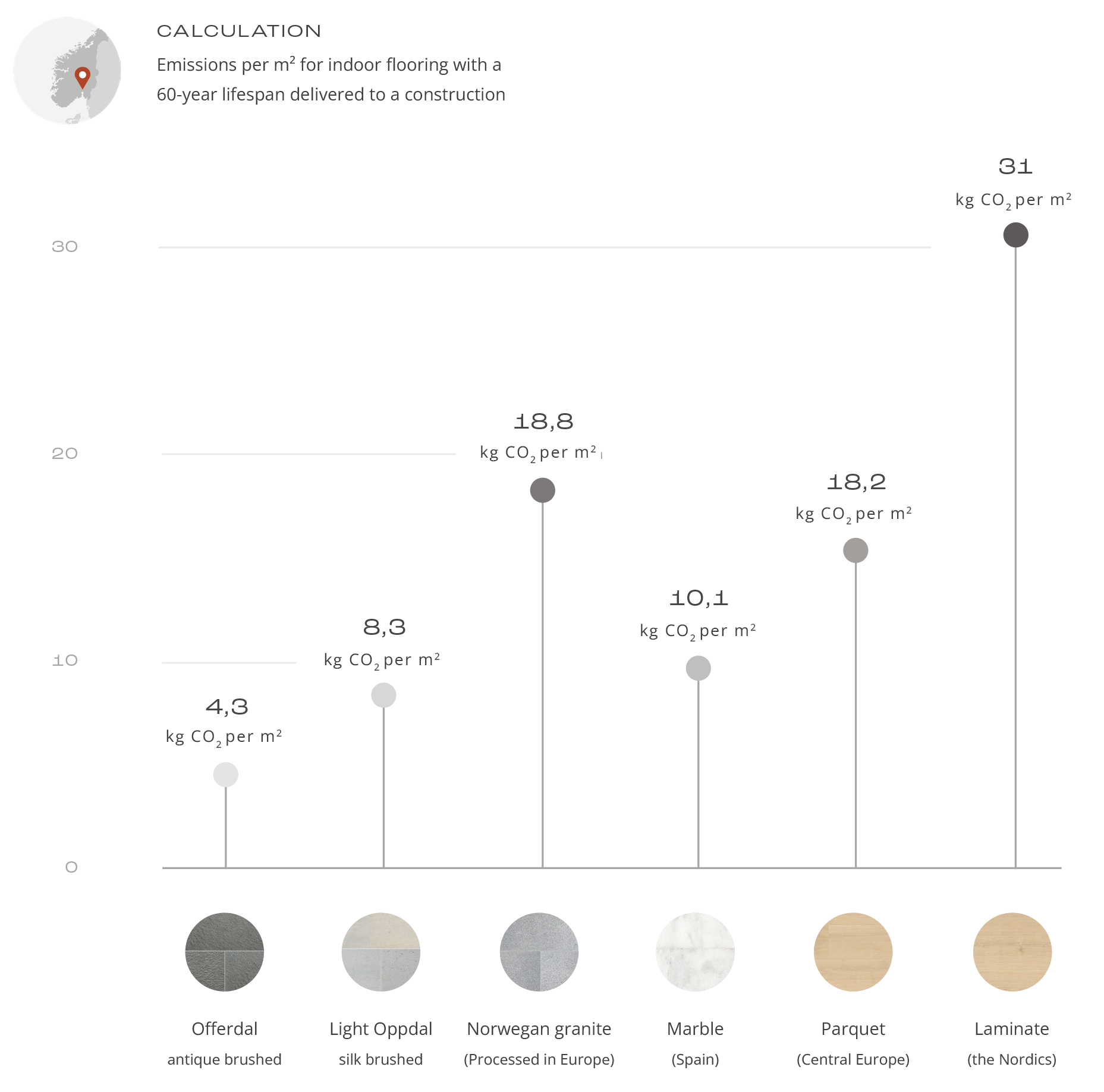

Slate tiles from Offerdal and Oppdal are compared to Norwegian granite (processed in Europe), Spanish marble, and parquet and laminate from Central Europe.

Result:

Offerdal slate provides 7,000 kg CO₂-eq lower emissions than laminate for 200 m² of flooring. Low carbon footprint and long lifespan make slate a competitive flooring material in terms of environmental performance.

Choosing Offerdal slate instead of laminate from Central Europe for 200 m² of indoor flooring reduces emissions equivalent to three years of daily car use (15,000 km per year) with an average petrol car.

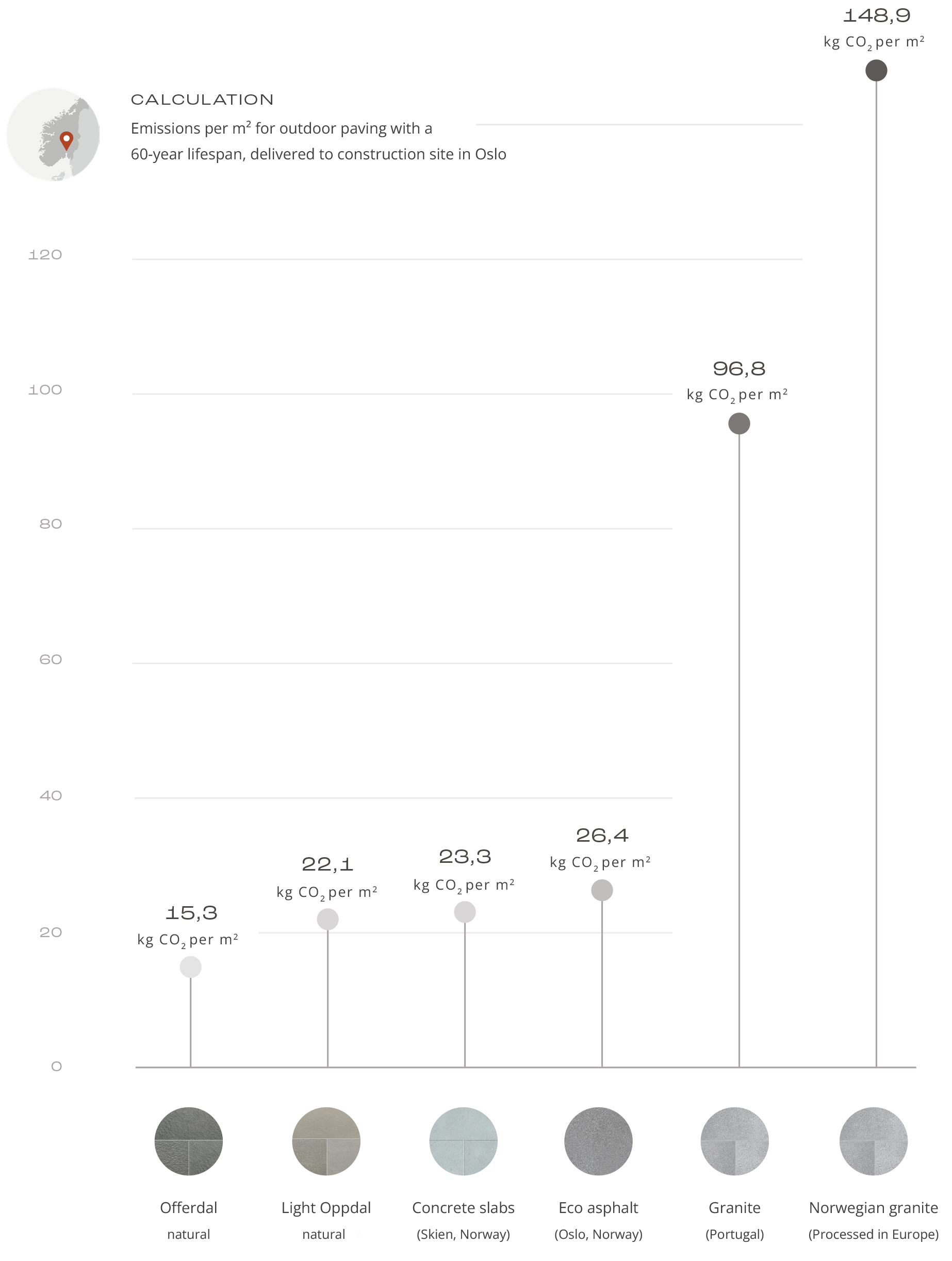

For paving, slate is compared to concrete slabs, eco-asphalt, Portuguese granite, and Norwegian granite processed in Europe. Material thickness is adjusted for technical performance (e.g. flexural strength).

Resultat:

Use of Offerdal quartzite generates only 30% of the CO₂ emissions compared to a Norwegian granite processed in Europe for an area of 200 m². Granite’s need for greater thickness and higher process energy contributes to the significant emission difference.

Covering a 200 m² outdoor area with Norwegian granite processed in Europe instead of Offerdal Natural slate increases CO₂ emissions by 26,720 kg – equivalent to the emissions from 213 round-trip flights between Oslo and Trondheim.

Note: These comparisons are based on a standardized scenario and should be viewed as indicative. Actual emissions may vary depending on project location, material choices and technical solutions. The analyses can be used as a basis for early-phase decisions but should be supplemented with project-specific assessments.

Assumptions and method: The analysis was conducted by Asplan Viak in 2022 and is based on production, process and transport data for a standardized project located in Oslo. All emissions are stated in CO₂ equivalents and cover module A1–A4. For materials with shorter lifespans, required replacements are included in the calculations.

Substructures and project-specific adaptations are not included. Other available EPDs may show differing values depending on producer and methodology.