Reuse cases with slate

Slate has an inherent 100% reuse potential. To fully realise this, solutions for production, transport, installation and storage must be optimised. The circularity of the material depends both on its physical properties and on planning processes in the project.

Choosing appropriate installation methods, planning for dismantling and preparing for storage makes it possible to reuse slate from one building in another without material loss. This requires that reuse is considered early in the design process.

Circular material strategies require technical expertise and interdisciplinary coordination. Architectural, economic and technical sustainability must be addressed simultaneously. Documented examples show how slate from existing constructions has been reused in new buildings with complete material utilisation.

Overview of installation methods for slater where the full quantity of material can be dismantled and reused without loss. Guidelines for dismantling, cleaning and storage are included.

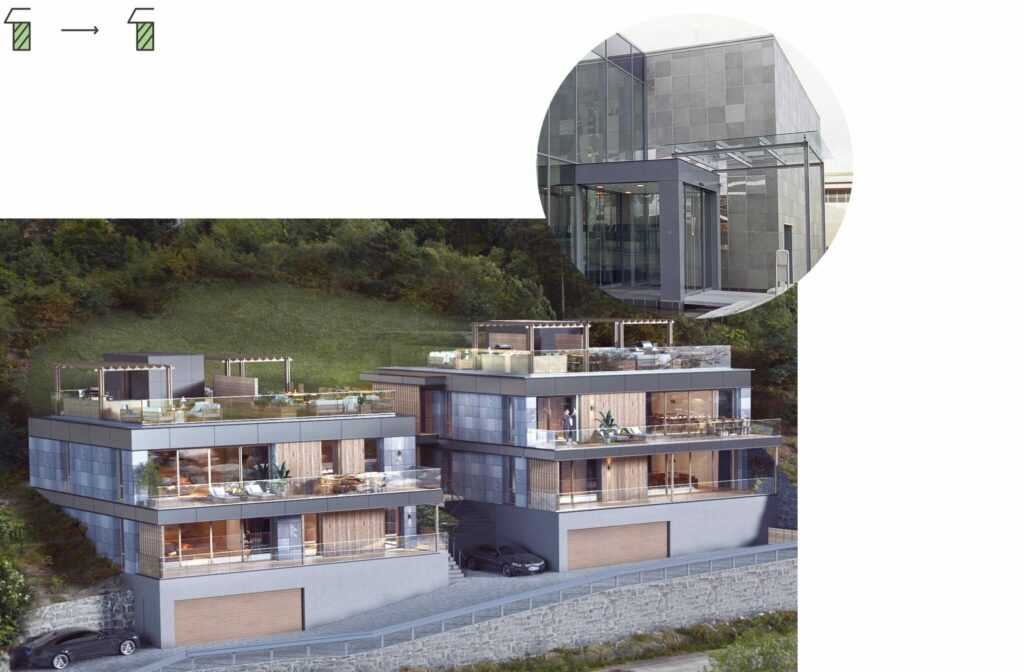

DALEVEIEN, STAVANGER, NORWAY

Façade slate from an office building owned by Lyse Energi was dismantled in connection with the demolition of an exterior wall after 20 years of use. The slate was stored for future reuse on the initiative of project manager and civil engineer Jon Aarrestad.

In 2025, the material was reinstalled as cladding on two horizontally divided duplex homes outside Stavanger.

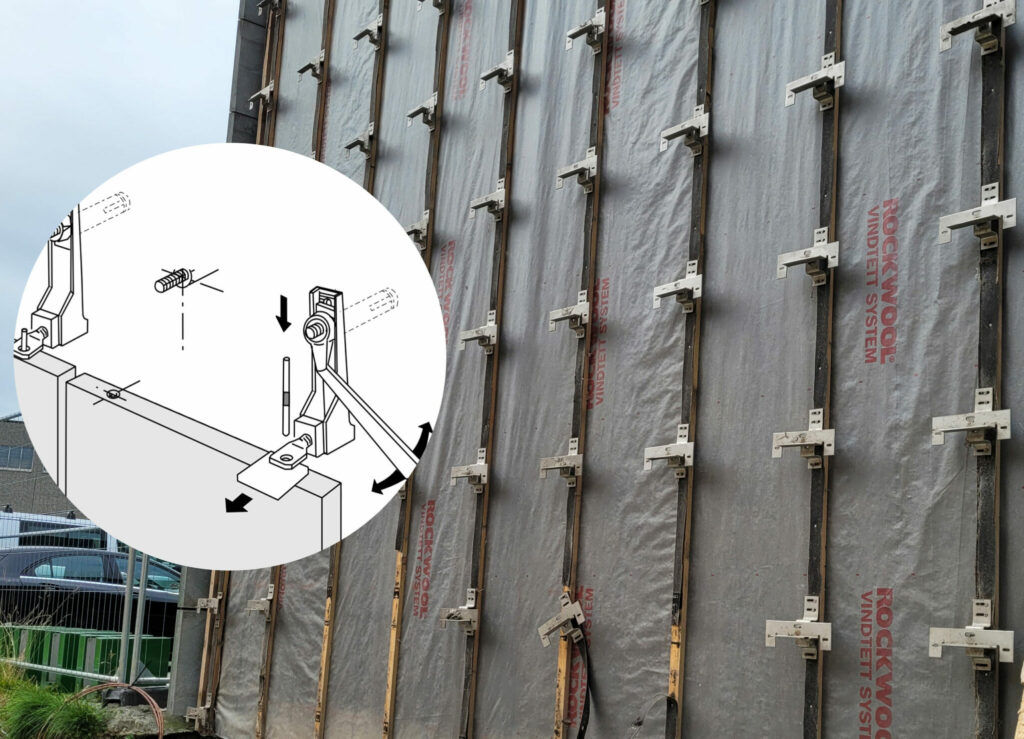

The slate was originally installed using an anchor system where blade bolts passed through holes in the edge of the slate tiles, fastened to base elements on the building’s structural frame.

During dismantling, the bolts were loosened without damaging the tiles, and both the slate and fastening system were fully reusable.

Original installation:

Concealed system with blade bolts and base elements

Actions taken:

Dismantling, storage, reinstallation in new structure

TECHNICAL UNIVERSITY OF DENMARK (DTU)

The DTU campus was designed and constructed in multiple stages between 1960 and 1974. The project was led by architects Eva and Nils Kappel, and the campus was shaped as a landscape, where slate walls act as structural and unifying elements between buildings and outdoor spaces.

Oppdal quartzite was used both indoors and outdoors in the original construction and remains a consistent material throughout the campus architecture. In DTU’s current strategic campus plan, it is stipulated that the slate structures should be preserved where possible. When modifications are needed, the stone is saved for future reuse.

Original construction:

Two layers of slate masonry with cast core and through-jointing

Actions taken:

Dismantling performed manually by loosening the top course with crowbar, hammer and chisel. Stones were taken down by hand and cleaned of mortar with an electric chisel before storage and reuse.

PRIVATE HOME, OPPDAL, NORWAY

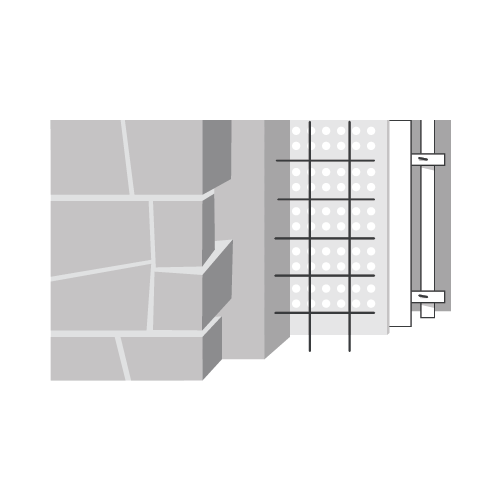

Slate from a barn built in the 1930s was reused in a new private home on the same site. Part of the original masonry façade was preserved and integrated into the new building as a storage room and terrace. The remaining slate was dismantled and reused as cladding in the new construction.

The wall consisted of mortared natural stone with cast backing and wall anchors. Demolition was carried out using machinery. The stones were manually cleaned with an electric chisel and stored on pallets.

The new substructure for slate cladding was built with wind barrier, battens and OSB boards to create a ventilated air gap. Foundation membrane was applied for moisture protection, and reinforcement mesh added for structural stability. The slate was then re-mortared with joints, backing and anchors.

Original construction:

Masonry façade in slate with backing and anchors

Actions taken:

Mechanical demolition, cleaning, storage and reinstallation with adapted substructure

Overview of documented fastening solutions for façades, roofs, stairs, walls and outdoor surfaces. All methods have been evaluated for dismountability and reuse potential. Each method includes guidelines for dismantling, cleaning and storage.

Method overview and dismantling guide