Guide: Interpreting and Comparing EPDs

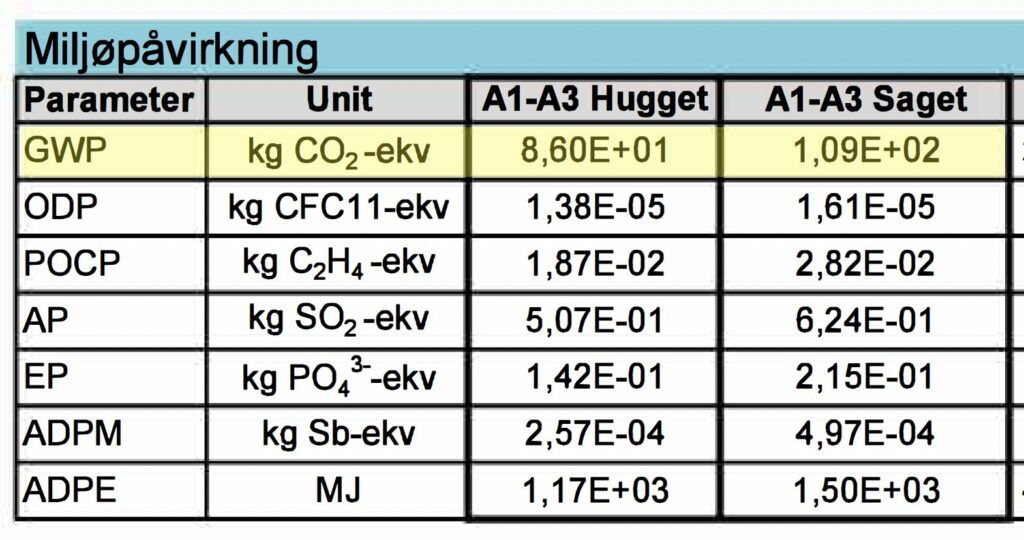

An Environmental Product Declaration (EPD) is a standardized document that summarizes the environmental impact of a building material based on life cycle assessment (LCA). The EPD provides a basis for product comparison and documentation of material choices.

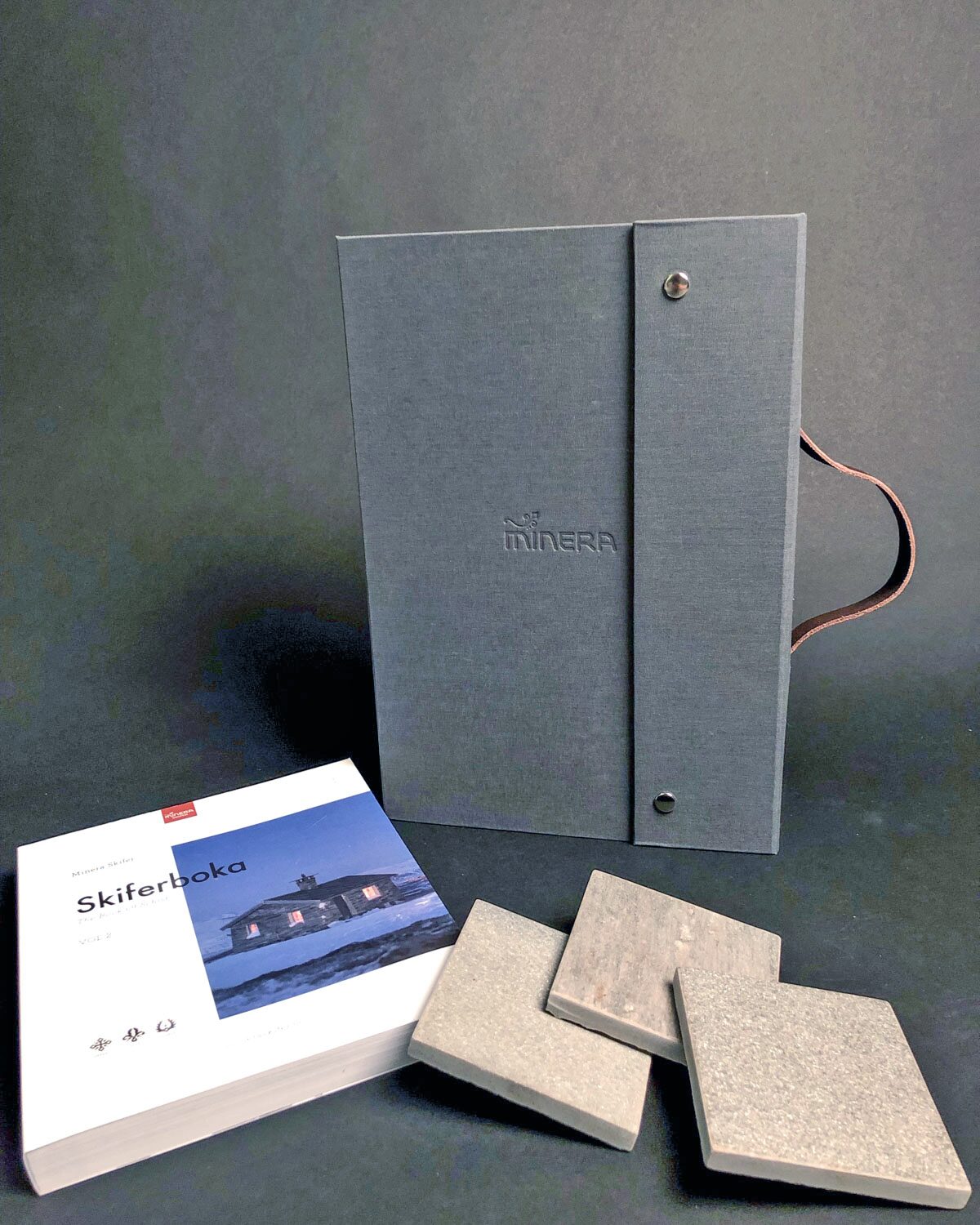

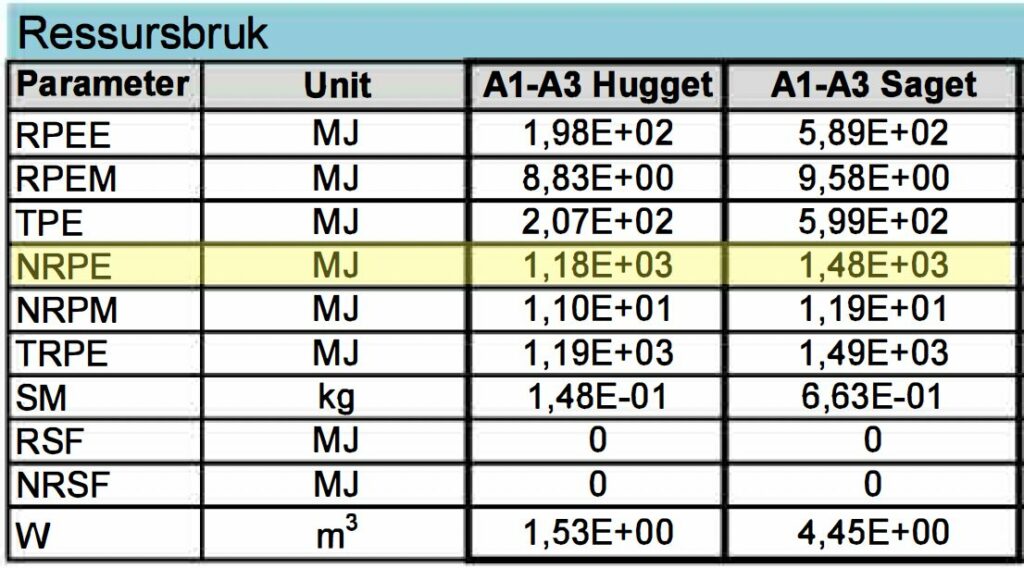

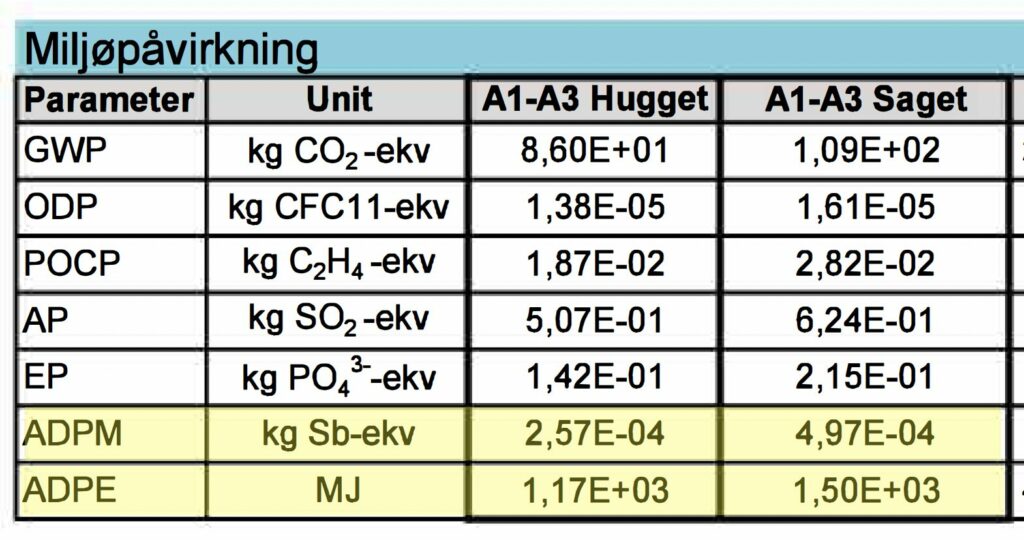

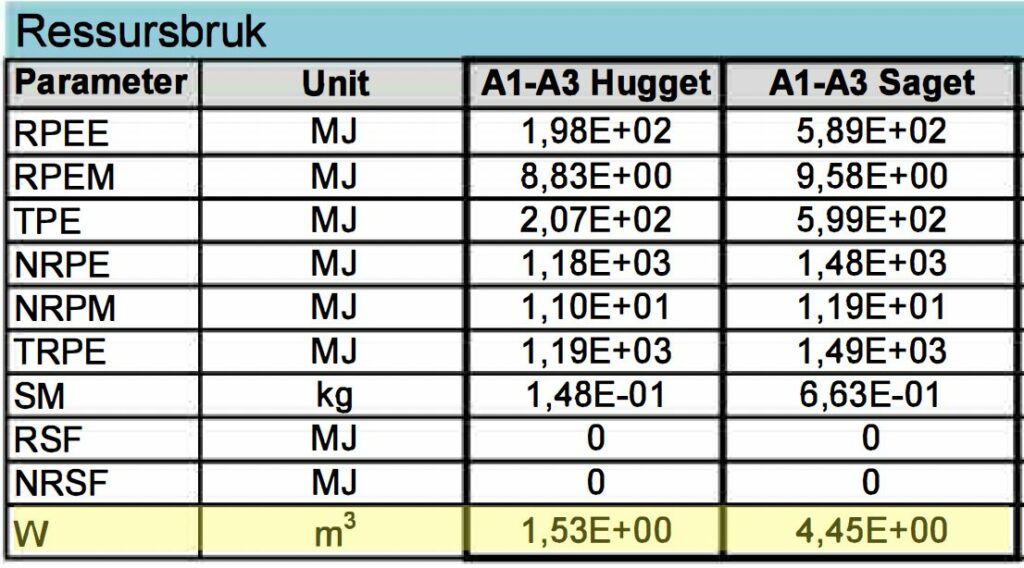

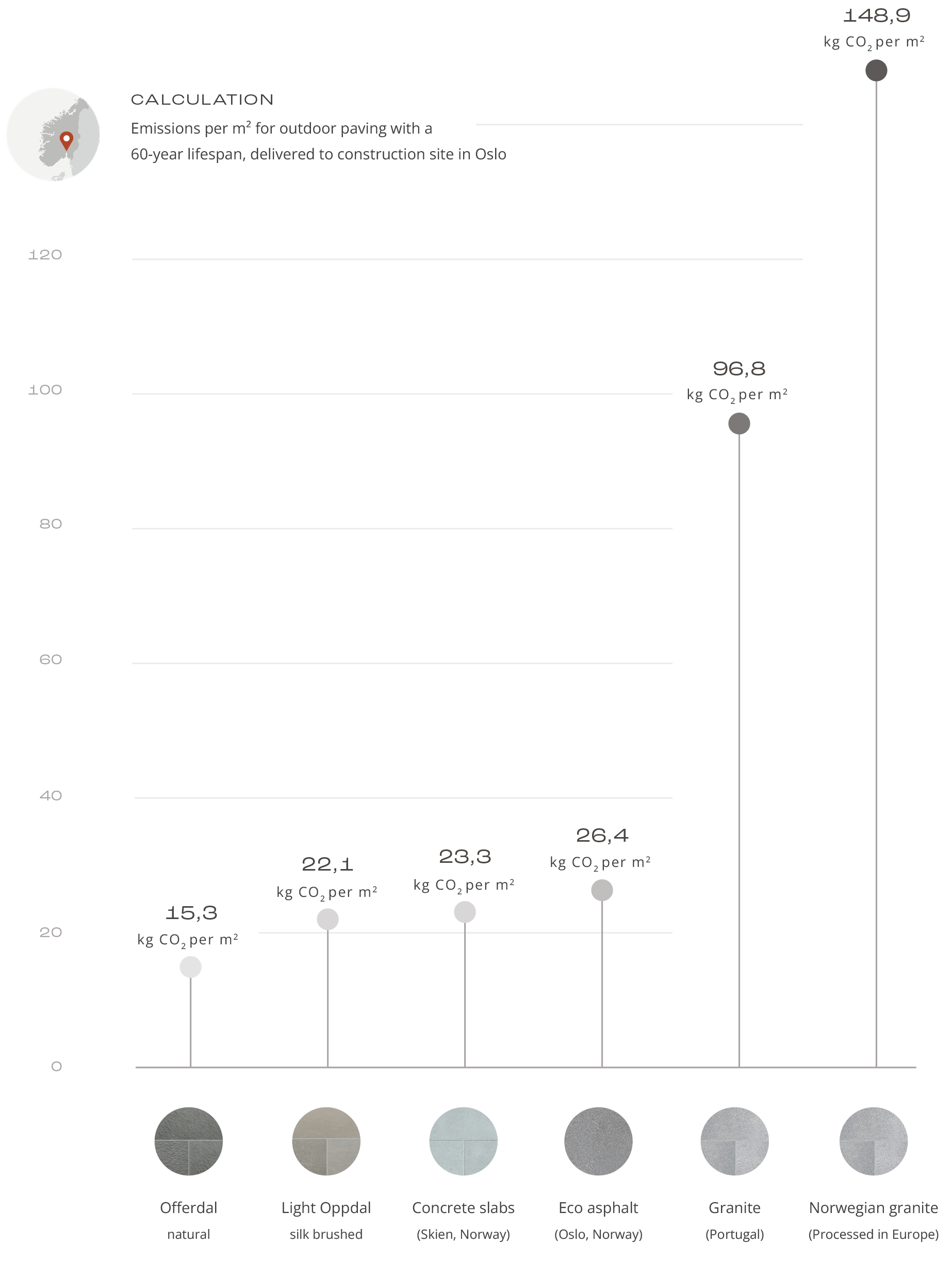

This guide outlines four key indicators in EPDs and how they can be interpreted and compared. The examples are drawn from the EPD for Oppdal slate natural cut, with either chiseled or sawn edge.