| Attention Fields | Technical solution | Exampel with slate | |

| (Scroll down to see the images) | |||

| Executed using transverse tactile ribs or bars that provide a warning before a level change. | Integrated in tiles: Slate tiles with milled grooves. The grooves can be delivered pre-filled with contrast material such as stone, metal, or PU, or filled on site. | Image 6: Slate with milled grooves filled with Akemi Akepox anti-slip. | |

| Surface-mounted solution: Tactile ribs made of metal, rubber, or polymer are glued directly to the surface of the slate. The elements are delivered separately and placed in the desired pattern. | Image 1: Slate with transverse tactile bars | ||

| Hazard Warning Surfaces | |||

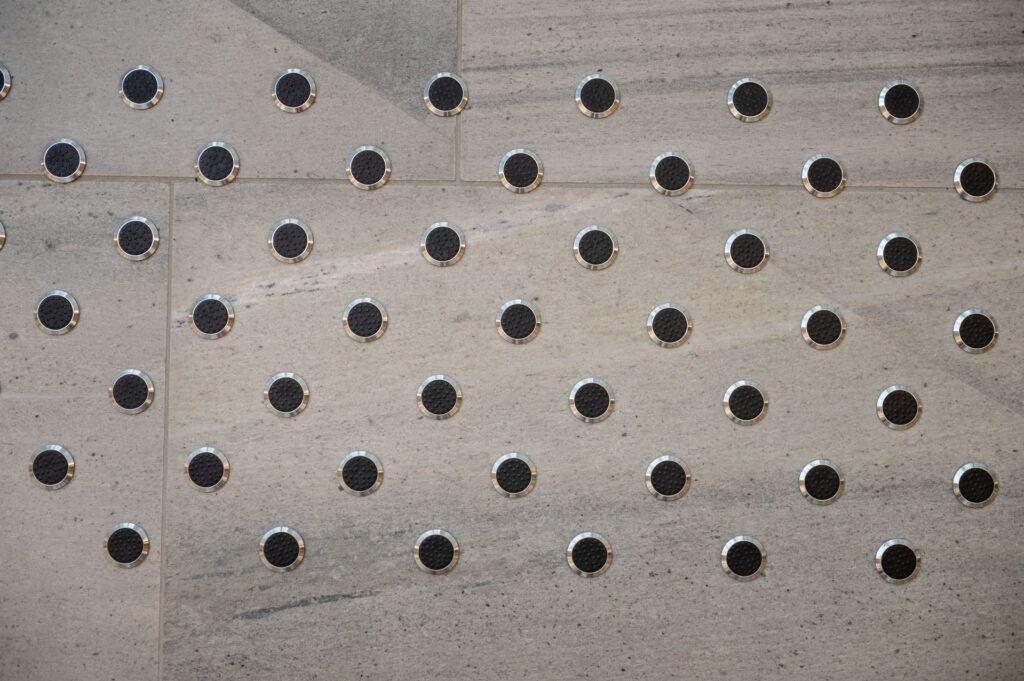

| Executed using round tactile studs in a systematic pattern, mounted on or recessed into the surface. | Integrated in tiles: Slate tiles with milled holes for tactile studs. The studs can be pre-mounted in the tile or glued on site. The studs may be made of metal, polymer, or other contrast materials. | ||

| Surface-mounted solution: Tactile studs mounted directly on the slate surface in a defined pattern. They can be glued or screwed in place and are delivered loose for on-site mounting. Common materials are stainless steel, brass, or composite. | Images 2, 7, 8: Round tactile studs surface-mounted on slate | ||

| Contrast Marking of Stairs and Landings | |||

| Executed using contrast zones or stair nosings in another material or color. | Integrated in tiles: Slate steps or tiles with milled grooves for contrast strips. The grooves can be delivered pre-filled with contrast materials such as slate, marble, metal, or colored compound, or filled on site. | Images 5, 6, 7: Slate with milled grooves filled with marble / Akemi Akepox anti-slip / rubber | |

| Stair nosing or contrast zones in another material glued directly to the surface of the slate. The solution may also consist of a separate strip in contrast material mounted at the front edge of the step. | Images 4, 8: Slate with stair nosing in contrast slate mounted flush with step | ||

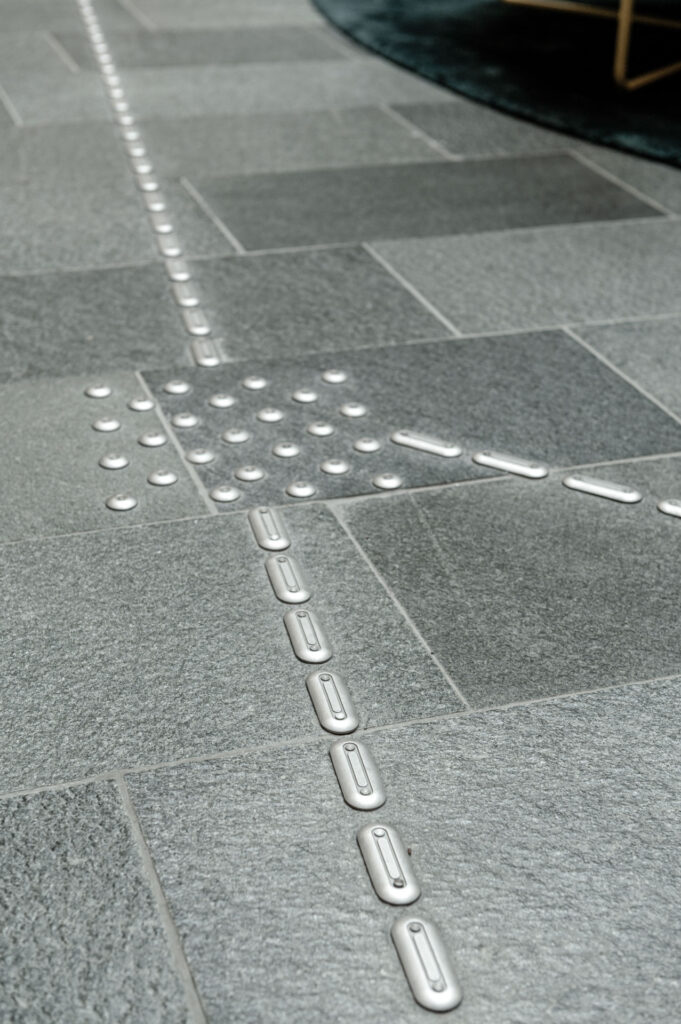

| Tactile Guiding Line | |||

| Executed using longitudinal ribs or bars providing tactile guidance in open spaces. | Tactile ribs are mounted directly on the slate surface and form a continuous guiding line. Ribs can be glued or screwed in place, depending on substrate and product. For direction changes, a square center point in the same material is used. | Image 3: Guiding line with 300 x 300 mm center point for direction change on slate |

| This overview introduces different methods for attaching tactile elements – such as studs, strips, prefabricated fields, and guiding lines – to natural stone, especially slate. The choice of method should always be assessed in collaboration with the tactile product supplier and the responsible designer. | |

| ADHESIVE FIXING (CHEMICAL BOND) | |

| Suitable for indoor use or smooth, dry outdoor surfaces. The substrate must be clean, dry, and grease-free. Smooth stone surfaces should be lightly roughened if necessary. | |

| 3M VHB tape for indoor studs/strips (quick installation, strong adhesion) | |

| 1-component MS polymer adhesive for natural stone for simple mounting | |

| 2-component adhesive for natural stone provides high strength for outdoor use | |

| MECHANICAL FIXING (DRILLED SOLUTIONS) | |

| Common method for outdoor installation or high-traffic areas: | |

| Holes are drilled with a stone drill bit (not hammer drill). Adhesive must be applied in and under the element. | |

| Studs and strips with pins are pressed into drilled holes filled with adhesive. | |

| PREFABRICATED FIELDS / TILE SOLUTIONS | |

| Plates with stud patterns (e.g. 30×30 cm) can be glued with mounting adhesive. | |

| For outdoor use, flexible 2-component adhesive and optionally hidden mechanical fixing are recommended. | |

| Fields can be recessed into the stone surface to prevent edge wear. | |

| SUBSTRATE PREPARATION (CRITICAL FOR ADHESION) | |

| Impregnation and wax must be removed before gluing | |

| Smooth surfaces should be lightly sanded and vacuumed | |

| Cleaning with isopropanol or similar removes dust and grease | |

| INDOOR VS OUTDOOR | |

| Tape or adhesive works in controlled/dry indoor environments, while a combination of adhesive and pins is recommended for durability and weather exposure: | |

| Studs (dots) | |

| Indoor: ape or adhesive directly on tile/slate | |

| Outdoor: Pin in drilled hole + 2K adhesive | |

| Guiding strips | |

| Indoor: Self-adhesive or glued to smooth surface | |

| Outdoor: Plugged metal strip in drilled hole (use template) or 2K adhesive | |

| Tactile plates/fields | |

| Indoor: Glued with mounting adhesive (optionally combined with tape) | |

| Outdoor: Glued with flexible 2K adhesive, optionally screwed (hidden). Preferably recessed slightly into the stone |

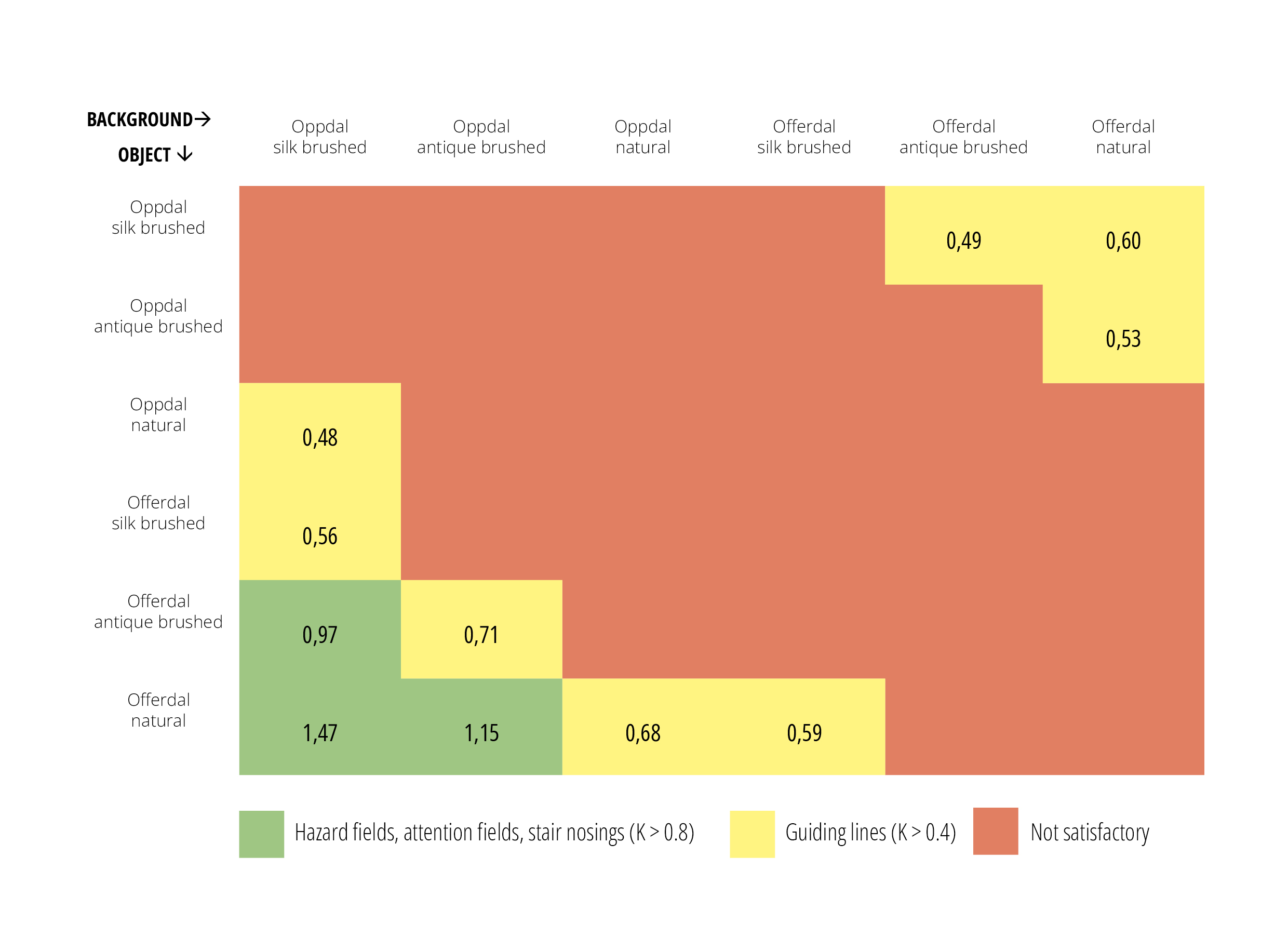

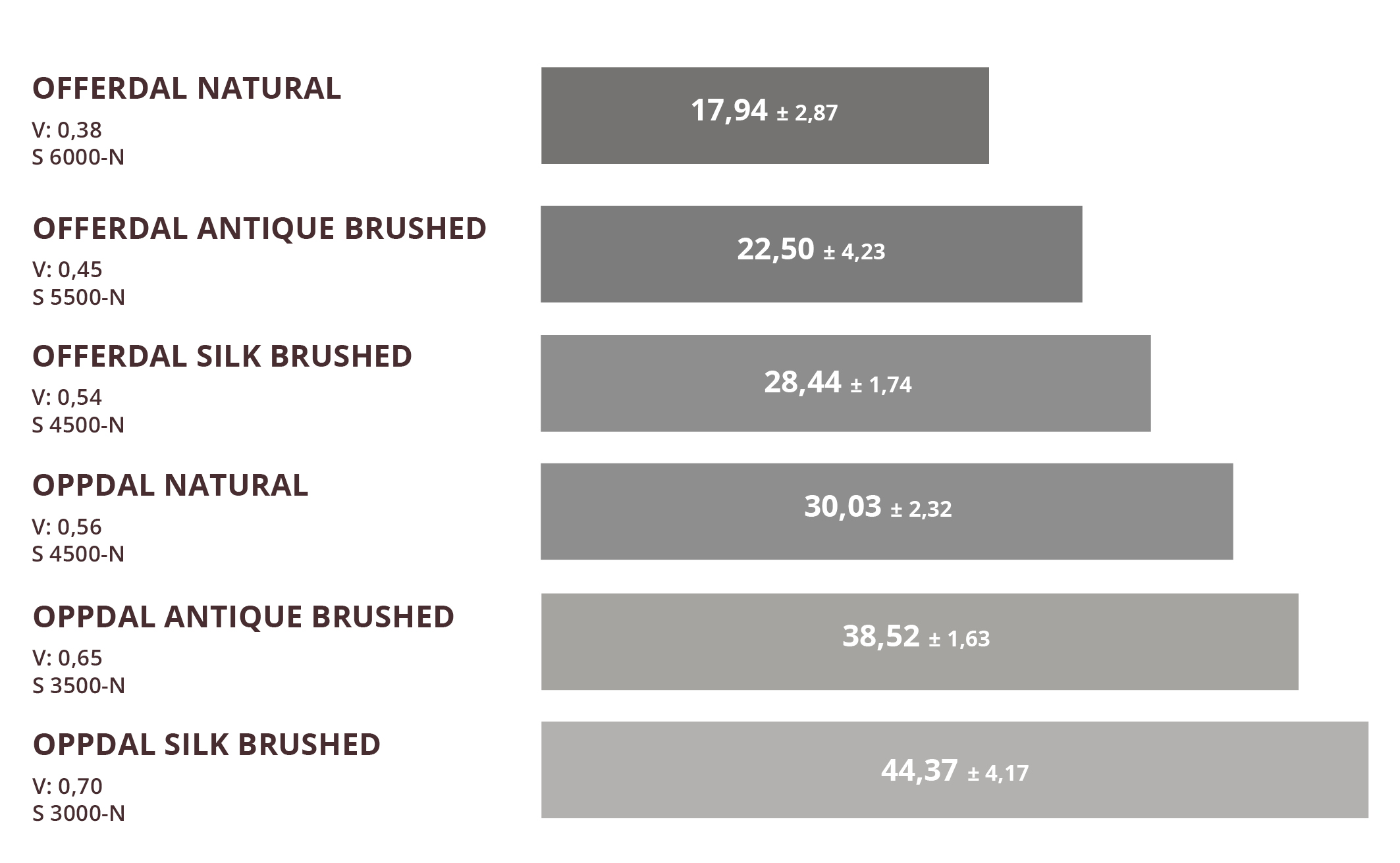

| Average of 10 slate samples measured with NCS Lightness Meter. This is a visual and analog tool – evaluation may vary between individuals and lighting conditions. It provides estimates as an initial design-phase tool but is not intended for precise documentation. | |||

| Y is used to calculate luminance contrast between two materials (use contrast calculator available for download). | |||

| Luminance contrast is calculated using the formula (Y₁ – Y₂) / Y₁, where Y₁ is the object and Y₂ is the background. | |||

| Type of slate | NCS Lightness (V) | Reflectance Value (Y) | Standard Deviation Y |

| Light Oppdal Natural | 0,56 | 30,03 | ± 2,32 |

| Light Oppdal Antique Brushed | 0,65 | 38,52 | ± 1,63 |

| Light Oppdal Silk Brushed | 0,70 | 44,37 | ± 4,17 |

| Offerdal Natural | 0,38 | 17,94 | ± 2,87 |

| Offerdal Antique Brushed | 0,45 | 22,50 | ± 4,23 |

| Offerdal Silk Brushed | 0,54 | 28,44 | ± 1,74 |

| See also the visual cross table below. | |||

| Suggested combinations based on luminance contrast thresholds used in Norwegian regulation. These thresholds are used in national building regulations (e.g. Norway), but are not defined in current European standards (EN 17210 or EN ISO 21542). These thresholds are used in national building regulations (e.g. Norway), but are not defined in current European standards (EN 17210 or EN ISO 21542). | |||

| Background = the main surface (e.g. a stair tread) | Object = the contrast marking (e.g. stair nosing) | ||

| ≥ 0.8 for stair nosings, hazard fields, attention fields, handrails | Background | Object | Contrast(K) |

| Offerdal Natural | Oppdal Antique Brushed | 1,148 | |

| Offerdal Natural | Oppdal Silk Brushed | 1,474 | |

| Offerdal Antique Brushed | Oppdal Silk Brushed | 0,972 | |

| ≥ 0.4 for guiding lines and contrast surfaces | Bakgrund | Objekt | Kontrast (K) |

| Oppdal Natural | Oppdal Silk Brushed | 0,477 | |

| Oppdal Antique Brushed | Offerdal Natural | 0,534 | |

| Oppdal Silk Brushed | Offerdal Natural | 0,596 | |

| Oppdal Silk Brushed | Offerdal Antique Brushed | 0,493 | |

| Offerdal Natural | Oppdal Natural | 0,675 | |

| Offerdal Natural | Offerdal Silk Brushed | 0,586 | |

| Offerdal Antique Brushed | Oppdal Antique Brushed | 0,712 | |

| Offerdal Silk Brushed | Oppdal Silk Brushed | 0,56 |

Relevant regulations and guidelines:

EN 17210:2021 – Accessibility and usability of the built environment (CEN)

European CEN standard describing functional accessibility requirements for stairs, tactile surfaces, visual contrast and orientation elements in built environments. Includes terminology, performance requirements and applicable use cases. Note: the full standard must be purchased, but this official summary page provides the scope, publication date, committee details and references.

EN ISO 21542:2021 – Building construction – Accessibility and usability (ISO)

International ISO standard offering detailed technical guidance on accessible building environments, including requirements for luminance contrast, stair dimensions and tactile guidance. The abstract page includes objectives, design considerations, and a structural overview. Note: full document must be purchased.

European Accessibility Act – Directive (EU) 2019/882 (EUR-Lex)

EU directive setting accessibility requirements for products and services, particularly relevant for public procurement, transport, communication and digital interfaces. Full legal text is available free of charge via EUR-Lex.

Slate offers unique possibilities for accessible and inclusive solutions – from tactile guiding lines to non-slip surfaces and contrast markings. We help you find the best solutions that combine aesthetics, functionality, and durability.

Get in touch – we are happy to assist with your project!