How to glue flagstones of slate

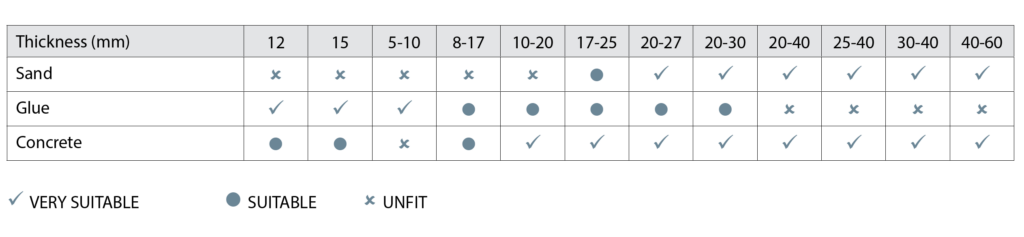

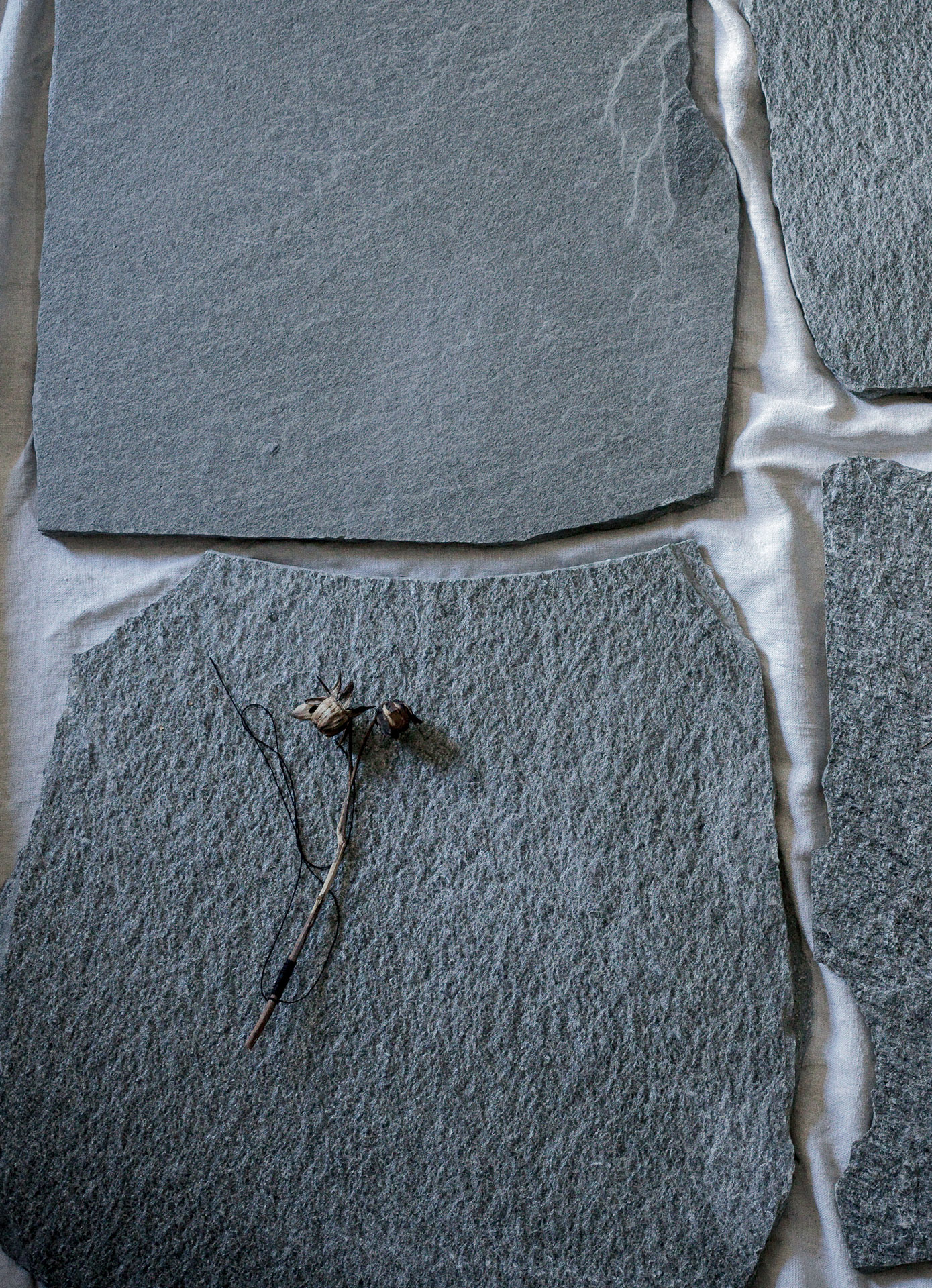

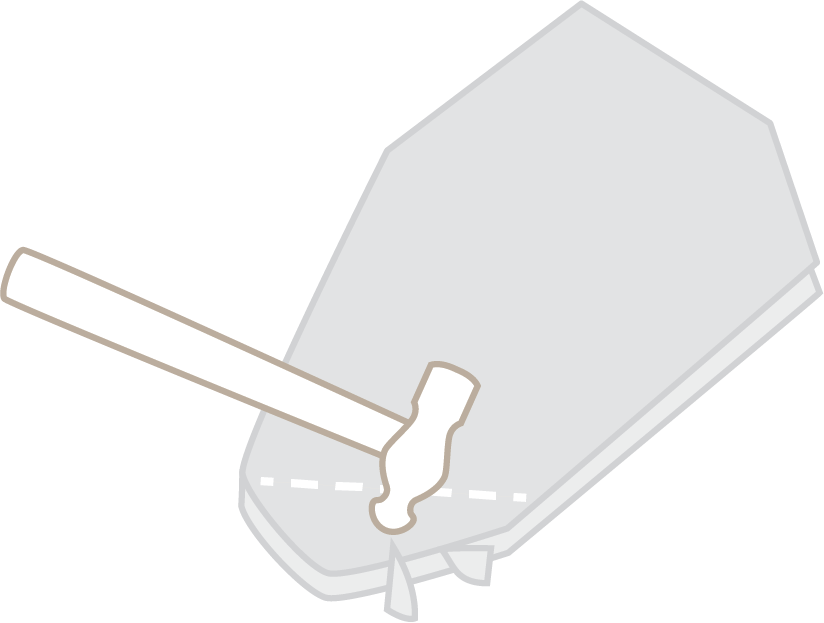

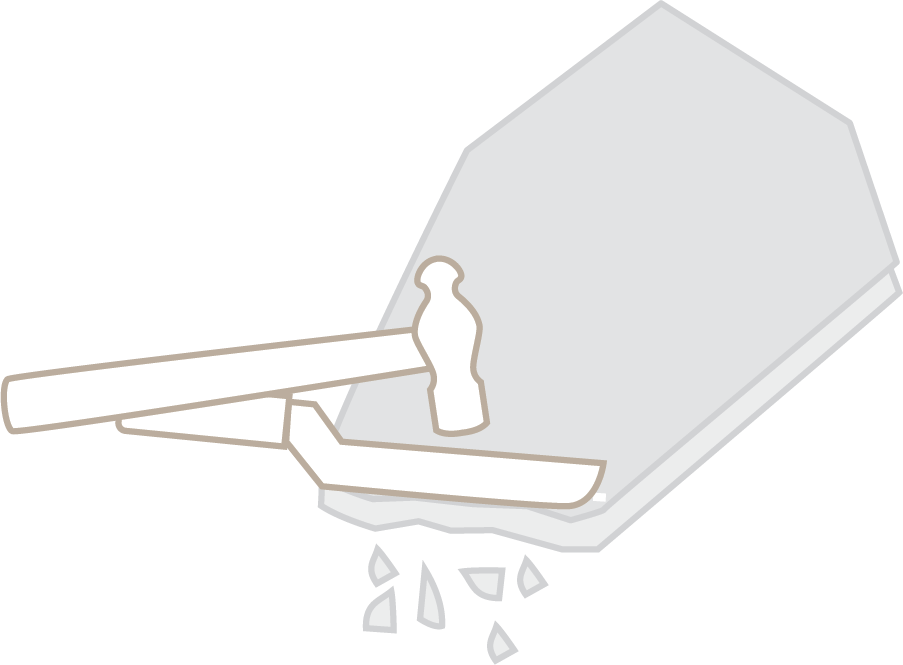

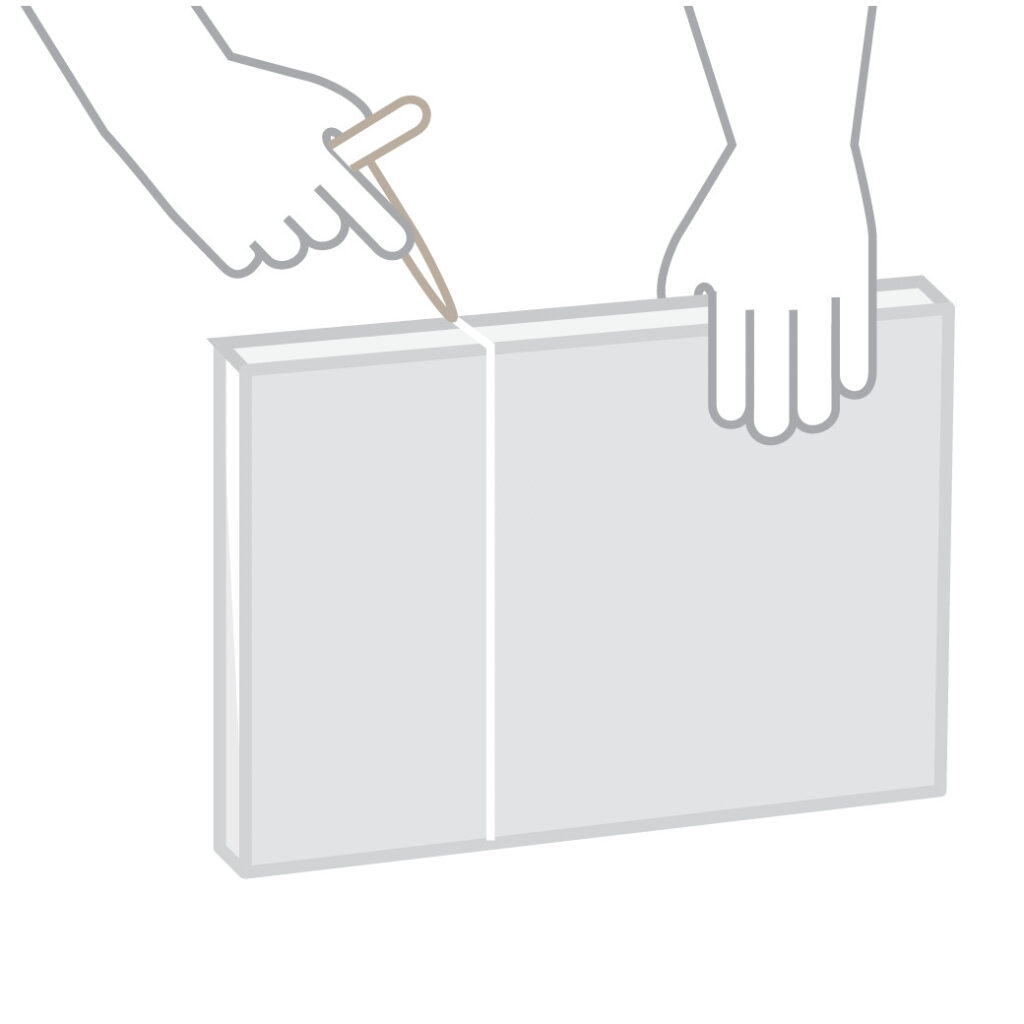

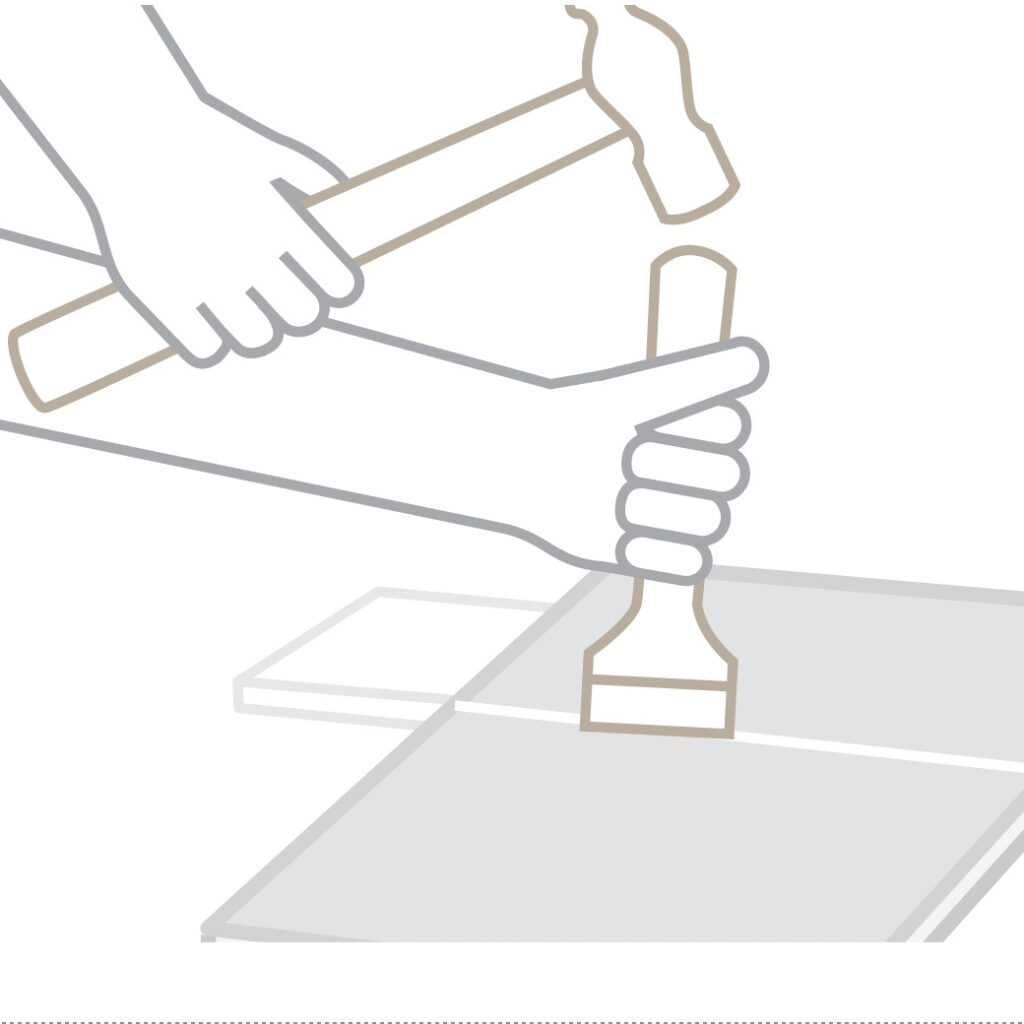

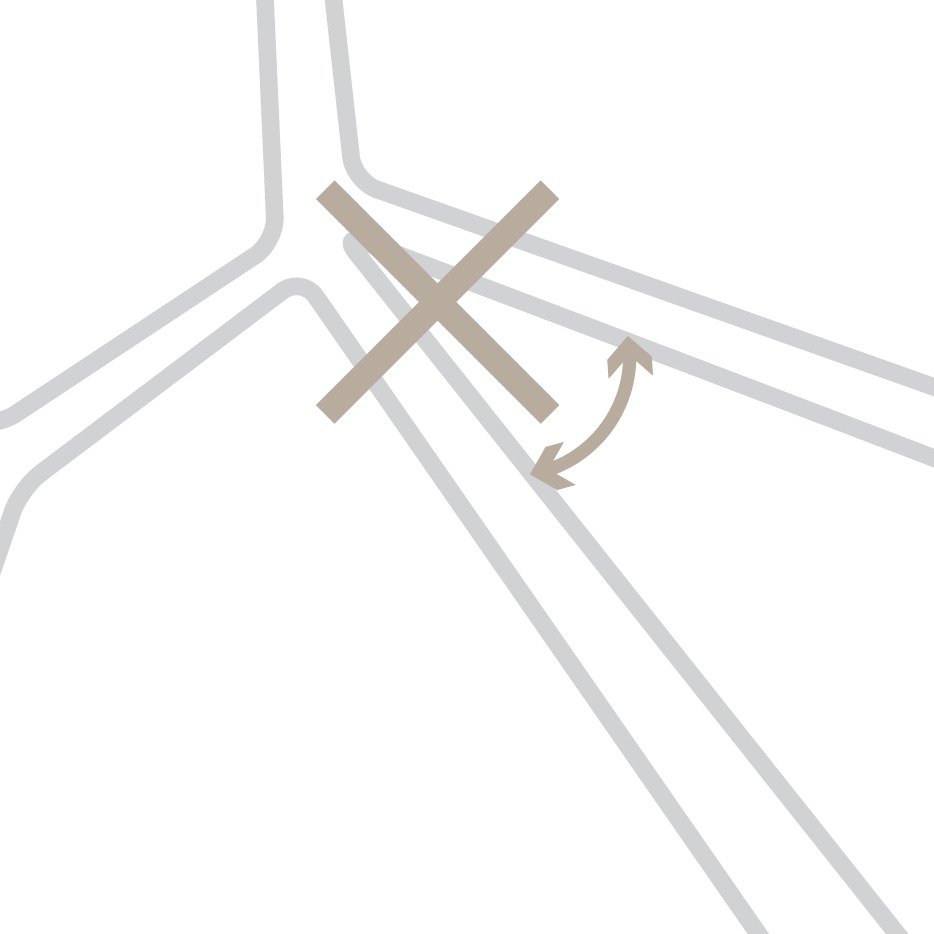

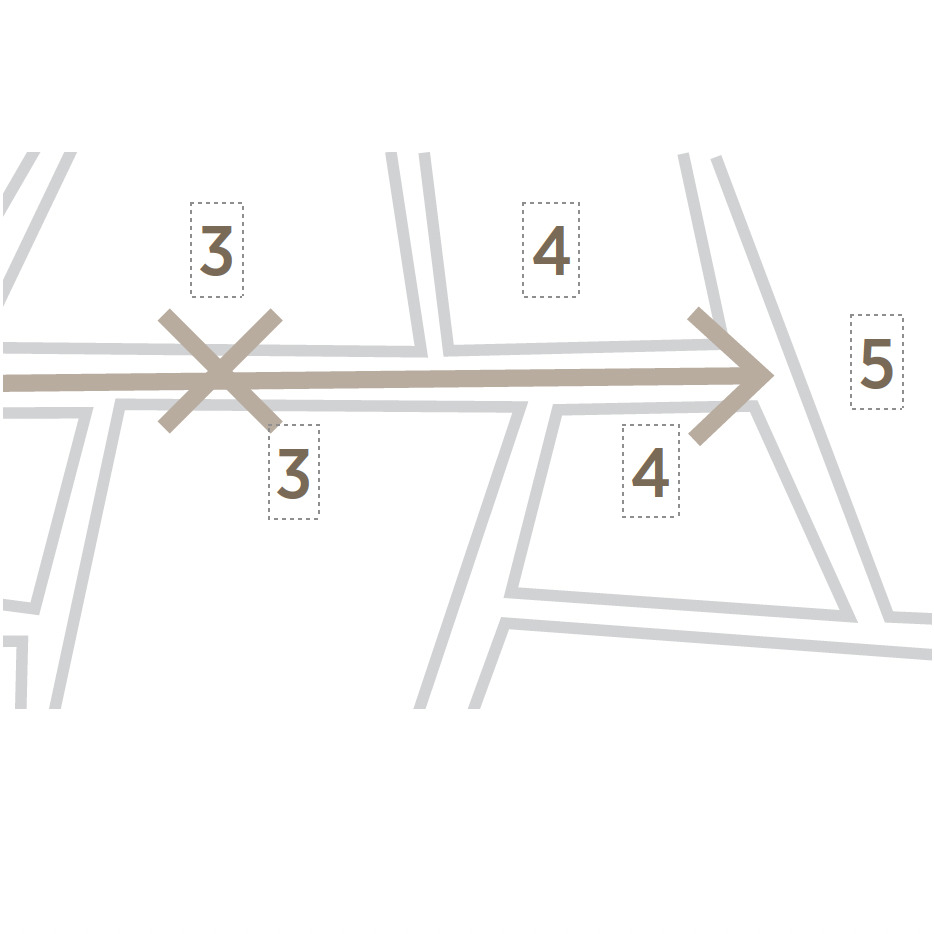

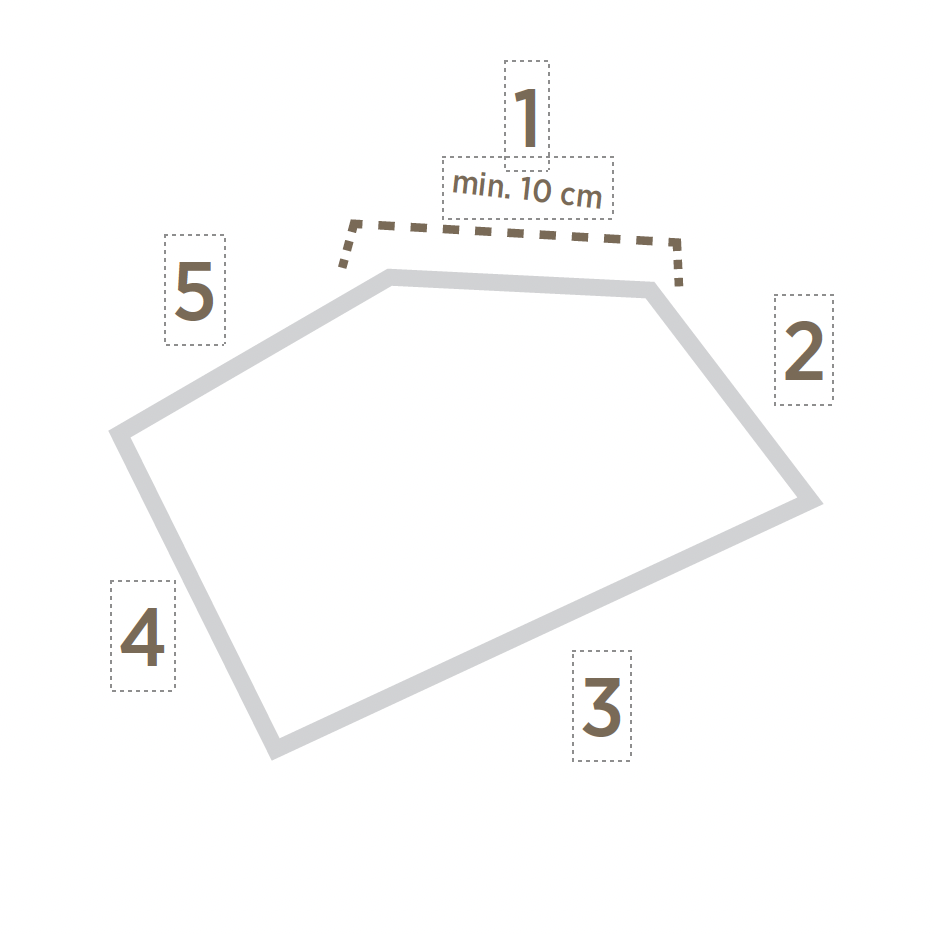

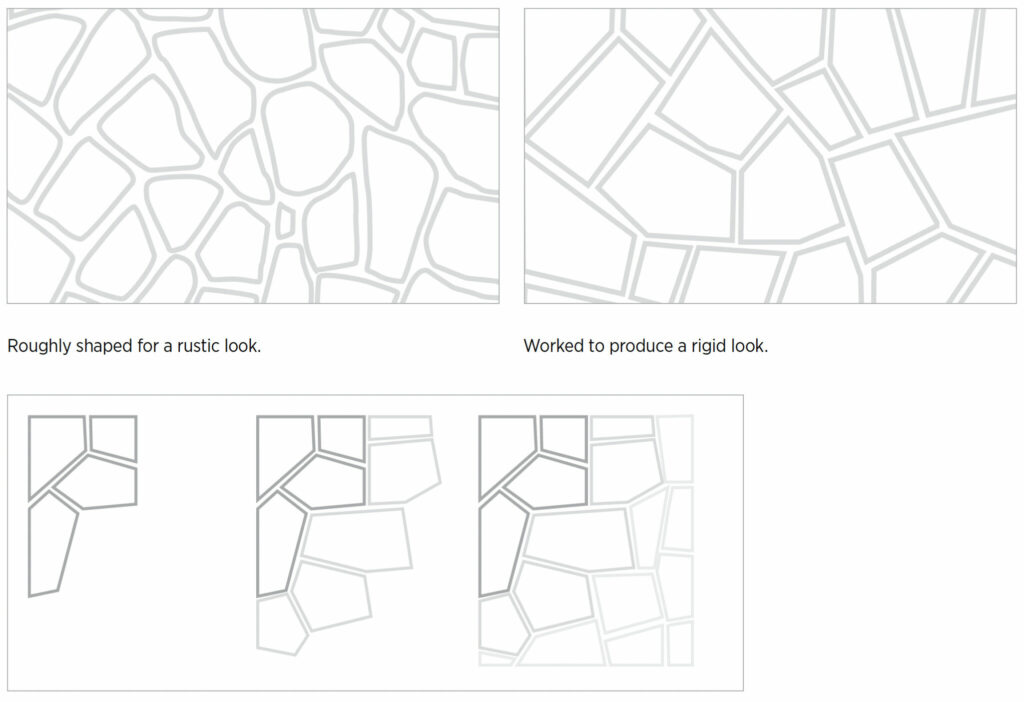

Choose the type of slate and tile dimensions according to how you want the final look to be, and then the thickness according to the load to which you expect the tiles to be exposed. Then you can shape the slate tiles by cutting/shearing/slicing corners and edges. NB: Don't throw away the left-overs! They are great to use as decorative stones, either in plant pots or flower beds.